Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.

Early Access: New Deals & Products | Sign Up For SMS Alerts

Early Access: New Deals & Products | Sign Up For SMS Alerts

Get Points. Earn Discounts! | Join Loyalty Rewards

Get Points. Earn Discounts! | Join Loyalty Rewards

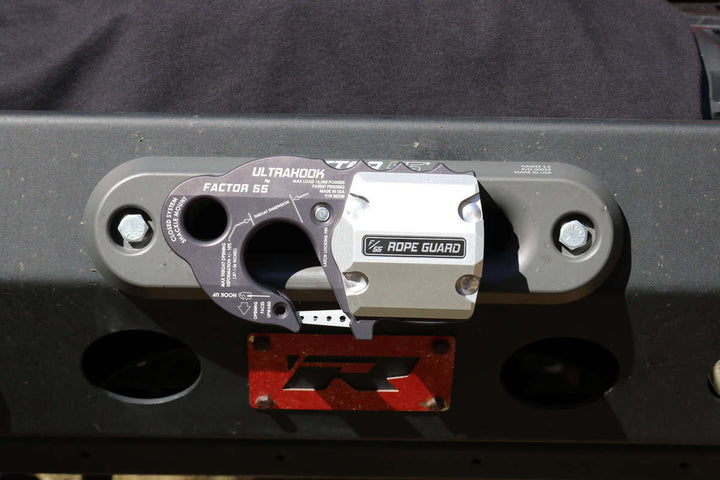

For you hardcore off-roaders and off-road trainers, the new UltraHook Rope Guard provides complete synthetic rope protection from damaging UV light as well as impact and abrasion damage. As you can see, when using the Rope Guard, all exposed synthetic rope surfaces are positioned behind the guard and fairlead, allowing you to use the Rope Guard as a skid surface when attempting to climb tall vertical obstacles. Made from Kaiser billet 6000 series aluminum and clear anodized for corrosion protection. Easy installation with 4 drive rivets. Keep your synthetic winch rope where it belongs – out of the sun and behind the fairlead.

Engineered and Made In The USA.FOR THE FOLLOWING PRODUCT APPLICATIONS; FACTOR 55 ULTRAHOOK

| Weight | .4 lbs |

|---|---|

| Dimensions | 7 × 4 × 1 in |

We recommend that the FlatLink or UltraHook first be removed from your winch line prior to the Rope Guard installation. Then, remove all rubber pieces from your FlatLink or UltraHook product. A little prying from a flat blade screwdriver should do the trick in popping out the rubber barbs. You will need to reinstall two of the rubber pieces after the Rope Guard installation is completed. We recommend that you place the FlatLink on top of a piece of wood on the ground or workbench surface prior to hammering in the drive rivets. Be sure to orient the Rope Guard in the correct direction (slot facing the rear) prior to proceeding with the rivet installation. For the UltraHook, make sure that the plane of the rubber pad surface is held flat to the wood surface for one side of the rivet installation and pivot the UltraHook over to the other surface for the remaining rivet installation. Now simply insert the 4 included drive rivets and using a ¼ inch punch, hammer the drive rivet posts down until the posts are flush with the top of the rivet head. Reinstall the rubber pads (lubricate the barbs) on the opposing side and you are done.

Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.

Spend $99 and up on any order and earn free shipping (continental USA only). Other conditions may apply.

We manufacture premium quality adventure bags in Virginia, USA. Built better and guaranteed for a lifetime.

Sign up for our weekly email updates. Don't miss exclusive deals, product announcements, limited runs and more.

SIGN UP FOR EMAIL UPDATES & GET 10% OFF!

For you hardcore off-roaders and off-road trainers, the new UltraHook Rope Guard provides complete synthetic rope protection from damaging UV light as well as impact and abrasion damage. As you can see, when using the Rope Guard, all exposed synthetic rope surfaces are positioned behind the guard and fairlead, allowing you to use the Rope Guard as a skid surface when attempting to climb tall vertical obstacles. Made from Kaiser billet 6000 series aluminum and clear anodized for corrosion protection. Easy installation with 4 drive rivets. Keep your synthetic winch rope where it belongs – out of the sun and behind the fairlead.

Engineered and Made In The USA.FOR THE FOLLOWING PRODUCT APPLICATIONS; FACTOR 55 ULTRAHOOK

| Weight | .4 lbs |

|---|---|

| Dimensions | 7 × 4 × 1 in |

We recommend that the FlatLink or UltraHook first be removed from your winch line prior to the Rope Guard installation. Then, remove all rubber pieces from your FlatLink or UltraHook product. A little prying from a flat blade screwdriver should do the trick in popping out the rubber barbs. You will need to reinstall two of the rubber pieces after the Rope Guard installation is completed. We recommend that you place the FlatLink on top of a piece of wood on the ground or workbench surface prior to hammering in the drive rivets. Be sure to orient the Rope Guard in the correct direction (slot facing the rear) prior to proceeding with the rivet installation. For the UltraHook, make sure that the plane of the rubber pad surface is held flat to the wood surface for one side of the rivet installation and pivot the UltraHook over to the other surface for the remaining rivet installation. Now simply insert the 4 included drive rivets and using a ¼ inch punch, hammer the drive rivet posts down until the posts are flush with the top of the rivet head. Reinstall the rubber pads (lubricate the barbs) on the opposing side and you are done.